Ifayile yeRotary amanqaku ezinyo-5.18

Sonke siyazi ukuba kwishishini lemveliso yokugaya, kukho imveliso ethandwa kakhulu - ifayile ye-carbide rotary.Silandela izibalo ezingaphelelanga.

Siye safumanisa ukuba ngokusekelwe kwiinkcukacha-manani ezingaphelelanga ubomi benkonzo ye-carbide burr bude, obuphindwe kalishumi ngaphezu kwesixhobo sensimbi esinesantya esiphezulu kwaye ngaphezu kwamaxesha angama-200 aphezulu kunolo lwevili lokusila i-alumina.Ngezantsi ziimilo zezinyo ezahlukeneyo esizinikezelayo ngokweemfuno ezahlukeneyo zokusila.

1.Single-cut burs: Ukusika okusemgangathweni kwezicelo jikelele.

2.Double-cut burs: Sika kabini ngenjongo yokusetyenziswa ngokubanzi.Ukuphucula ulawulo kunye nokunciphisa chips.

I-3.Alu-cut burs: I-Fast Mill inqumle ukususwa ngokukhawuleza kwempahla yezinto ezithambileyo ezingenayo i-ferrous kuquka iiplastiki.

Ifayile yentsimbi ingene ngaphakathi-5.18

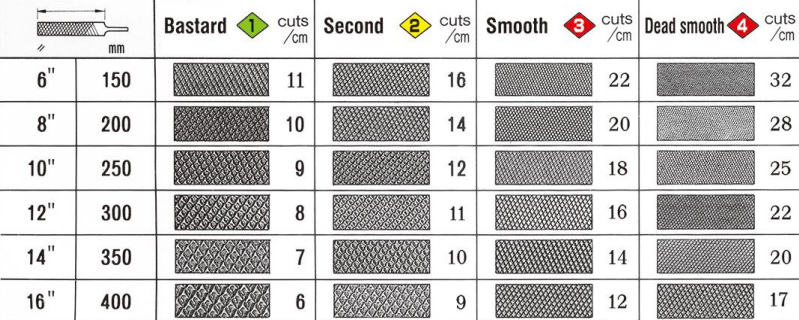

Ukuba unomdla wokwenza ubugcisa bakho, okanye ufuna isixhobo sokupolisha izinto, ke ifayile yethu yensimbi iya kuhlangabezana neemfuno zakho, ngokwepateni yezinyo, inokwahlulwa ibe ziindidi ezine, ezizezi, i-bastard cut, i-second cut, i-smooth cut. , ukufa okugudileyo ukusikwa.Ngokukodwa ngokweemfuno ezahlukeneyo zokugaya, kufuneka ukhethe iintlobo ezahlukeneyo zokusika.

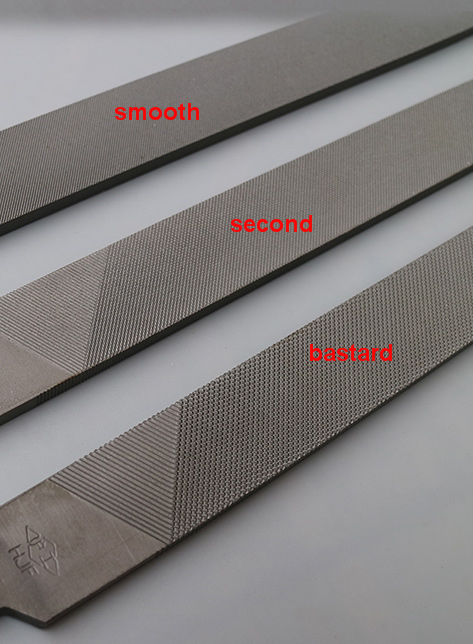

Kulo mfanekiso sinokubona iipateni ezintathu ezisetyenziswa ngokuqhelekileyo zamazinyo.

I-1.Bastard Cuts ifanelekile kwi-workpiece enzima kunye nokubunjwa kwangaphambili

2.I-Second Cuts ifanelekile kwi-machining kunye nesibonelelo somatshini esikhulu kune-0.5mm.Umatshini omkhulu wokusika umthamo unokuqhutywa ukususa inxalenye kunye nesibonelelo esingaphezulu se-workpiece.

I-3.I-Smooth Cuts ifanelekile kwi-machining kunye ne-machining allowance ye-0.5-0.1mm.Zinokupholiswa ngononophelo ukuze zisondele kubungakanani obufunekayo bomsebenzi.

Ifayile ye-4.Dead Smmoth Cuts yifayile enamazinyo amancinci.Isiphumo sayo sokusika sincinci kakhulu.Isetyenziswa ikakhulu ukucheba uburhabaxa bomphezulu womsebenzi.Isetyenziselwa ukugqiba i-workpiece surface.

Yile ndlela esahlula ngayo imigca yamazinyo.

Ixesha lokuposa: Jun-21-2022