Ukusetyenziswa kwe-carbide burrs:

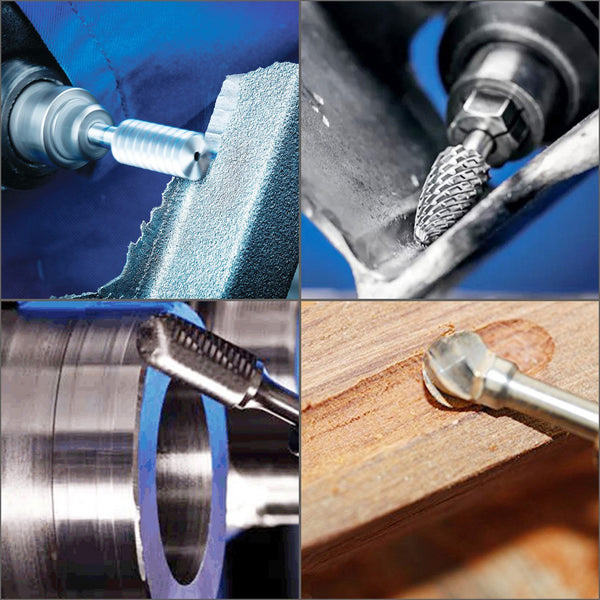

Ifayile ye-Tungsten carbide rotary isetyenziswa ngokubanzi koomatshini, iimoto, ukwakha iinqanawa, ishishini lemichiza, ukukrola ubugcisa kunye namanye amasebe oshishino, umphumo uyamangalisa, eyona nto isetyenziswayo yile:

(1) ukugqiba zonke iintlobo zomngxuma wokungunda wesinyithi, njengokungunda kwezihlangu njalo njalo.

(2) zonke iintlobo zesinyithi kunye ne-non-metal craft crafting, isipho sobugcisa bokukrola.

(3) iiflange, ii-burrs kunye neewelds zokwenziwa ngoomatshini, ukubumba kunye neendawo zokuwelda, ezifana nefektri yokuphosa koomatshini, indawo yeenqanawa kunye nemizi-mveliso yeemoto.

(4) zonke iintlobo zamalungu omatshini ahlaza i-chamfering kunye ne-groove processing, ukucoca imibhobho, ukugqiba iindawo zomatshini zomgangatho ongaphakathi womngxuma, njengomzi-mveliso woomatshini, ivenkile yokulungisa njalo njalo.

(5) Ukulungiswa kwamalungu embaleki ye-impeller, njengomzi-mveliso wenjini yemoto.

Iimpawu eziphambili zefayile ejikelezayo:

Ifayile ejikelezayo ye-carbide enezi mpawu zilandelayo:

(1) Nasiphi na isinyithi (kubandakanya intsimbi eqinile) kunye nezinto ezingezo zentsimbi (ezifana nebhastile, ijeyidi, ithambo) ngaphantsi kwe-HRC70 inokwenziwa ngokuthanda.

(2) Inokubuyisela ivili elincinane lokusila ngomqheba kumsebenzi omninzi, yaye akukho lungcoliso luthuli.

(3) Ukusebenza kwemveliso ephezulu, amaxesha amaninzi aphezulu kunokusebenza kakuhle kwefayile yesandla, phantse ngokuphindwe kashumi ngaphezu kokusebenza kakuhle kwevili lokugaya elincinane elinesiphatho.

(4) Umgangatho wokuqhuba kakuhle, ukugqiba okuphezulu, unokucubungula iintlobo ngeentlobo zomgobo wokungunda ochanekileyo.

(5) ubomi benkonzo ende, ukuqina kuphindwe kalishumi kunesixhobo sentsimbi esinesantya esiphezulu, ukuqina kungaphezulu kwamaxesha angama-200 ngaphezu kwevili lokugaya ialumina.

(6) Kulula ukuyisebenzisa, ikhuselekile kwaye inokwethenjelwa, inokunciphisa ukuqina kwabasebenzi, iphucule indawo yokusebenza.

(7) Inzuzo yezoqoqosho iphuculwe kakhulu, kwaye iindleko ezibanzi zokulungisa zinokuncitshiswa ngamashumi amaxesha.

Ukwenziwa koomatshini be-CNC kunye nokwenziwa kwezandla:

Ewe kunjalo, kusekho abavelisi abathile abasenza iifayile ezijikelezayo ngesandla, kwaye iimveliso zabo aziqhelekanga xa zisetyenziswa.

Uthanda ukungcangcazela, ukwaphuka kweblade, ukunxitywa kunye nezinye izinto, ezikhokelela kumsebenzi omninzi ongathandekiyo.Ngelixa umatshini we-CNC uvelisa ukujikeleza.

Iiparamitha eziphambili zefayile, ezifana nobunzulu be-groove, ububanzi be-groove, i-groove concentration, i-cutter Angle kunye ne-Angle ejikelezayo, inozinzo oluphezulu.Isiphumo, ewe, kukuba le yokugqibela ikulungele ngakumbi ukusebenza, iqhuba kakuhle, isiphumo sokusebenza singcono, kwaye eyona isebenzayo iyonke.

Ixesha lokuposa: Jun-21-2022